Vision System – PE-700

Introduction

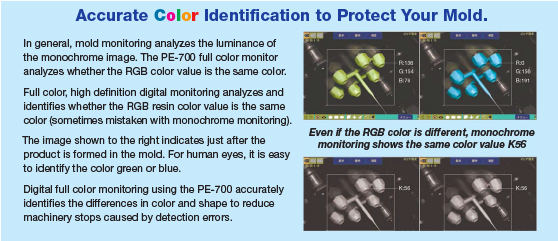

Comet’s PE-700, our newest model for mold protection, is now four camera compatible. As molds become larger, more complex, and refined the demand for product inspection and monitoring for defective parts, parts trapped in the mold, jammed or broken core pins, shorts and flash is essential. Digital color processing using four cameras improves the accuracy of detecting, and consistently finding, defects missed by a visual inspection from the machine operator.

Detect…

- Molded parts trapped in the cavity

- Residue on the mold

- Jammed or broken core pins and plugs

- Prevent shorts and flash

- Insert loading errors

- Both positions of the slide core and top pin centering

- Metal die casting errors

Features

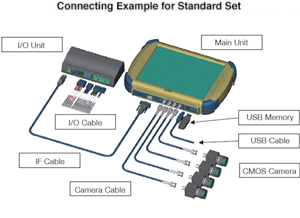

- Faster: Full color, high definition (2-million pixels) images are digitally processed and calculated at a speed of 0.012 seconds, and are adaptable for high speed injection molding with cycle times below one second or molds for large products.

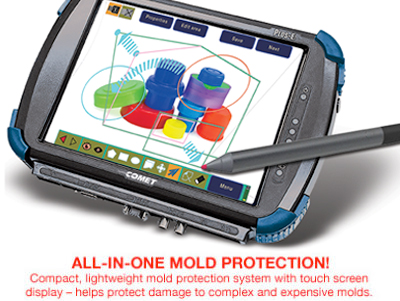

- Easier to Use: The large 10.4 inch, 1920 x 1080 pixel, touch-panel clearly displays HD images in full color. The intuitive interface has been redesigned and dramatically improved allowing quick, detailed monitoring area settings. Automated functions such as position correction and filtering improve monitoring precision and save presetting time.

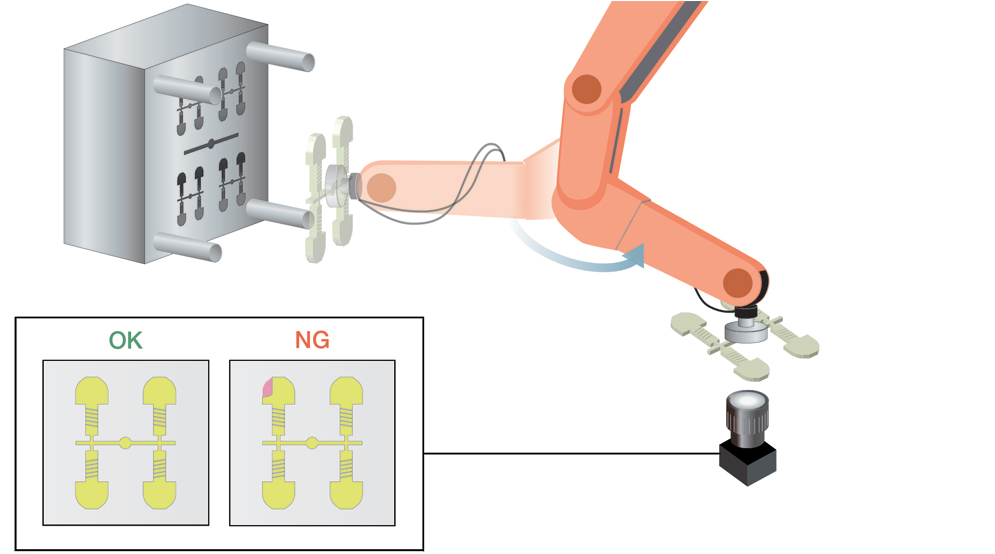

- Increased Productivity: Using the PE-700 with a molding machine that has a take-out robot, the PE-700 accurately checks and evaluates the product being picked for defects and stops the molding process to protect your expensive mold from being damaged or broken. Early detection and removing defective parts shortens the production process and reduces operator burden.

- Easy Operation: Easy, direct area settings, using the touch-panel, allow you to create a maximum of 30 areas including shapes like circles, polygons, or even a 20-sided shape.

- Lightweight: Weighs only 3 lbs. allowing you operate the unit with one hand while setting the parameters or monitoring the screen with the other.

- Precise: Digital color image analysis technology reduces machine stops by detecting errors and stopping the machine before any hazardous force can be put on the mold using non-contact vision technology.

- Flexible Shape Monitoring: Setting the monitoring area is key. Excluding unnecessary monitoring areas prevents errors often caused by the influence of ambient light for fast, accurate monitoring. Intuitively draw, stretch or move an area to shorten setup time. Simple icons help easily access necessary functions.

- Four-Camera Monitoring: One PE-700 with four cameras enables higher definition monitoring as well as large component monitoring.

- Image Recording: When an error is detected, the monitoring image of the “before/after” is recorded for five seconds. This enables the error to be investigated quickly. The recorded image is storable, if needed.

[/two_third_last]

[/two_third_last]

[/two_third_last]

[/two_third_last]