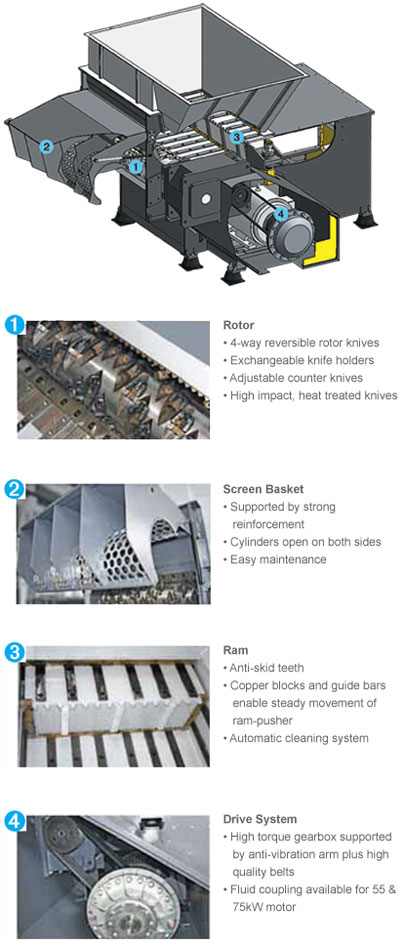

CSL-SS Large Heavy Duty Single Shaft Shredder

Introduction

Comet’s large, heavy duty CSL-SS series single shaft shredders are designed for processing plastic waste for recycling and reclamation, large or awkward extruder purgings, rejected parts, trim scraps, plastic profiles, film, synthetic fiber, electronic waste, plastic packaging, wooden pallets (including nails) and other organic materials.

Its large shredding chamber and loading hopper capacity, combined with a PLC controlled horizontal ram-pusher, ensures optimum material feeding to the rotor to achieve the most efficient performance.

Throughputs typically range between 3,307 to 26,455+ lbs./hr. (1,500 to 12,000+ kg/hr.) depending on the model, material type, and application.

Features

- Welded construction from heavy gauge steel plate.

- Inclined cutting chamber offers lower noise levels.

- Bearings and bearing housings are located outside the cutting chamber to prevent dirt, dust, or grease from entering the cutting chamber.

- Compact design minimizes factory space requirements.

- Precision machined rotors (forward set V-Rotor, standard).

- Oversized, outboard spherical rotor bearings prevent bearing damage due to product migration.

- Replaceable blade cover plates so no threads on the main rotor shaft can be damaged or become worn.

- Clearance between the rotor blades and screen is maintained at all times.

- Blade setting off the machine reduces maintenance downtime.

- Manual, electric and hydraulic chamber opening mechanisms to quickly access the cutting chamber for maintenance and cleaning.

- Rotor locking device ensures safety during maintenance.

- Stand alone electrical control panel using Siemens’ PLCs.

- Safety proximity switches on cutting chamber and access doors.