CG-XSP Heavy Duty, Single Pass Granulator

Introduction

Comet’s CG-XSP series heavy duty, high speed granulators are designed for high throughput size reduction of larger sized products in a single pass. They are ideal for processing various materials including glass-filled plastics, rubber, copper cable, etc. They can also be used for secondary granulation when positioned behind pre-shredders for recycling systems.

With a variety of rotor configurations, CG-XSP granulators have a wide range of applications including voluminous materials like plastic drums, crates and chairs; flexible materials like film, woven bags and rubber; and dense materials like profiles, thick sheets, as well as other general plastics, wood, paper, aluminum, foam, and mixed household and commercial waste. The CG-XSP series has numerous safety and wear protection features.

Features

- Welded construction from heavy gauge steel plate.

- Inclined angle, two-piece cutting chamber opens quickly for easy access and maintenance.

- Rotor and counter knives can be adjusted outside the granulator using a standard knife setting gauge.

- The distance between the rotor knife edge and the screen can be easily set and adjusted.

- Three rows of counter knives are mounted around the cutting circle. One row can be removed for different material applications.

- Oversized, outboard spherical rotor bearings prevent bearing damage due to product migration.

- Replaceable wear plates, made from specially produced steel, are mounted on both sides of the rotor.

- Screw conveyors are installed under the screen for material discharge.

- Blade setting off the machine reduces maintenance downtime.

- A rotor lock and rotor speed sensor is installed to ensure safety when doing maintenance.

- Compact design minimizes factory space requirements.

- Stand alone electrical control panel using Siemens PLCs.

- Safety proximity switches on cutting chamber and access doors.

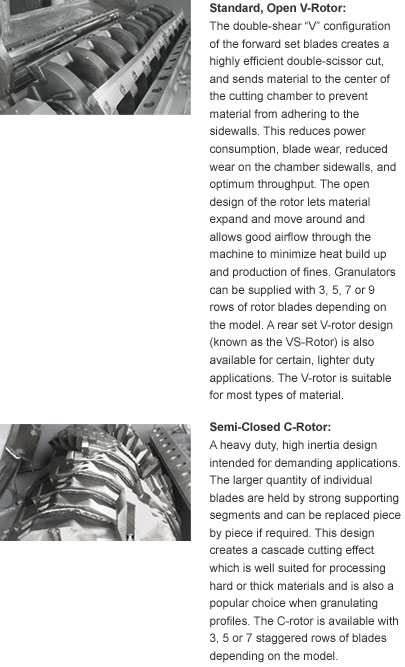

Rotor Types