CG-23/30/36 Central Granulator

Introduction

Comet’s CG-23/30/36 series sound-proof central granulators are designed for recycling waste or rejected parts from injection molding, blow molding or extrusion machines. This series is solid and dependable and features easy operation, quick blade replacement, and fast cleaning and maintenance. There are multiple machine sizes with cutting chamber openings up to 20″ (750mm) wide, various rotor speeds, and different rotor blade configurations to allow you to select the best granulator to suit your specific requirements.

Features

- Fully enclosed, completely sealed, sound-proof design assures low noise levels during granulation.

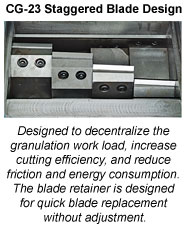

- Easy accessibility and maintenance to the cutting chamber ensures minimal downtime.

- Clamshell-like hopper opening and drop down screen chamber for quick blade replacement.

- Safety material curtain ensures no material sprinkling during granulation.

- CG-30/36 equipped with a preset knife jig.

- High quality solid steel blades for durability.

- Material inlet chute with adjustable angle for easy material feeding from a conveyor belt.

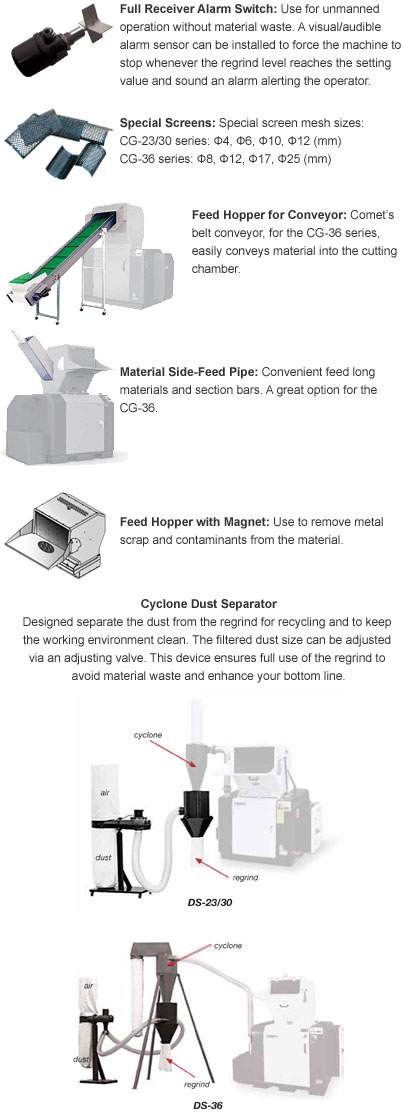

- Cyclone dust separator removes regrind dust and assists material collection even with the toughest materials.

- Dust collecting bag provides easy dust cleaning and reduces contamination.

- Compact footprint and multiple safety features.

- Equipped with electrical current relay, motor overload protection, and regrind conveying system.

Options