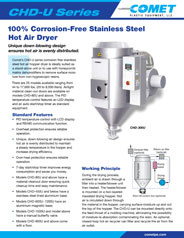

CHD-U Hot Air Hopper Dryer

Introduction

Comet’s CHD-U series corrosion free stainless steel hot air hopper dryers can be directly mounted onto a molding machine for quick, space-saving drying or mounted to a floor stand with a take-off box. This dryer series is ideally suited to use with honeycomb matrix dehumidifiers to remove surface moisture from non-hygroscopic resins.

Model capacities range from 25 to 1,850 lbs. There are multiple optional accessories to meet different production demands, such as hot air recycler, magnetic base, and maintenance ladder, etc.

Features

- PID temperature control with LCD display and RS485 communication features accurate temperature control, digital display, and auto start/stop functions.

- Overheat protection ensures reliable operation.

- Unique, down-blowing air design ensures hot air is evenly distributed

to maintain a steady temperature in the hopper and increase drying efficiency. - Double layer insulated structure ensures a uniform temperature with less heat loss.

- All material contact surfaces are made of stainless steel.

- Over-heat protection ensures reliable operation.

- 7-day automatic timer and sight glass window.

- Models CHD-80U and above have a material clean-out door ensuring quick cleanup time and easy maintenance.

- Models CHD-450U and below have a stainless steel lined aluminum base.

- Models CHD-600U~750U have an aluminum magnetic base.

- Models CHD-900U and above are equipped with a manual butterfly valve and floor stand.

Options

- Access ladder for models CHD-1500U and above.

- Heatless Regenerative Air Dryer for low dewpoint dry air without heat

to speed material drying. - Hopper magnets to capture metal scraps in the material to prevent damage

to the plasticizing screw. - Blower inlet filters and exhaust filters to filter the dust in the air.

- Magnetic base to capture metal scrap preventing contamination.

- Floor stands for easy installation and transportation of the dryer and hopper loader.