CCD Honeycomb Matrix Compact Dryer with Loading

Introduction

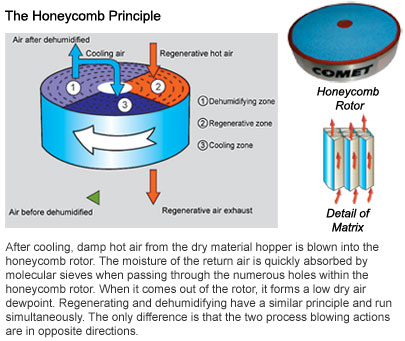

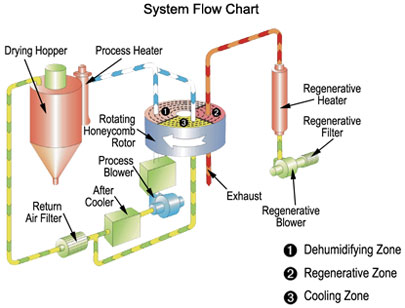

The CCD all-in-one honeycomb matrix dryers combine drying, dehumidifying, and portable two-stage (optional three-stage) conveying, all packaged into a single unit. The dryer is bundled with a hopper, cart, and built-in vacuum loader for mobile drying on demand. The honeycomb matrix rotor enables dehumidifying, regeneration, and cooling cycles to occur at the same time while delivering a dewpoint of -40°F (-40°C) or an optional -50°F (-45.5°C) if required. This series of dryers is especially suitable for drying hygroscopic plastics such as PET, PC, PBT, and PA..

Features

- Stainless steel construction for all material contact parts. Stainless steel receivers are controlled from the dryer panel.

- Molecular sieve/gel sintered honeycomb rotor provides low dewpoint air without contaminating raw material.

- Twin condensers and a mounted return air filter quickly and accurately cool down regenerative air.

- Return air filter mounted on the inside ensures a contamination-free honeycomb rotor.

- Drying temperatures up to 320°F (160°C), up to 35% operating savings.

- Non-proprietary PID microprocessor temperature control system with regenerative temperature settings, real time displays, and a weekly timer.

- Feeding system equipped with a shut-off valve to ensure no material is left in the conveying line.

- Insulated stainless steel drying hopper utilizes a down blowing design with cyclonic air exhaust to avoid heat loss and improve drying efficiency.

- Double water cooler ensures a lower return air temperature and dewpoint value.

- Equipped with a highly efficient drying hopper that takes up to 20% less floor space than previous versions.

Options

- Dewpoint monitor available on the control or portable.

- HMI energy consumption adjustment control saves up to 41% total power consumption and is convenient for machines running on automatic.

- Three-stage conveying for feeding two injection molding machines.

- Polished surface inside the hopper to prevent material contamination.

- Upgraded PLC and touch panel control.