CCAD-U Mini Compressed Air Resin Dryer

Introduction

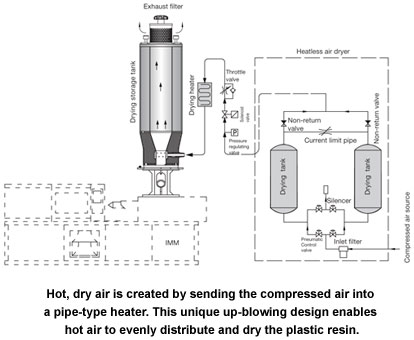

Comet’s CCAD-U compressed air dryer series removes moisture, water, oil, solid air particles, and other contaminants from compressed air, and integrates plastic drying and conveying into one compact unit. This feature makes it ideally suited for vertical and stand-alone injection molding machines where space is limited due to factory height. The CCAD-U series is perfect for small batch drying of commonly engineered plastics like ABS and PS, or as a pre-heating treatment before molding.

The CCAD-U is portable and can easily move from one injection molding machine to the next, and has both low noise and energy consumption levels.

Features

- Cost effective, compact, portable, and easy to install and operate.

- PID temperature controller reaches ±1°C.

- Drying is not influenced by ambient temperatures or humidity.

- CCAD-1U ~ CCAD-6U is equipped with a dual-layer, thermostable glass tube to easily view material levels.

- CCAD-12U ~ CCAD-40U is equipped with a contamination free stainless steel storage hopper.

- Compressed air pressure sensor ensures safe, reliable operation.

- Voltage outlet-type temperature controller is coupled with an SSR control loop prolonging service life.

- Overheat protection to avoid high temperatures.

- Air outlet filter reduces pollutants to the environment.

- Warning light monitors operation.

Options

- HAD heatless air dryer will enhance efficiency and reach dewpoints under -40°F.

- Couple the CCAD-1U ~ CCAD-6U with a Comet VL-50 venturi loader for automatic material feeding.

- Couple the CCAD-12U ~ CCAD-40U with a Comet SAL-1U vacuum loader for automatic material feeding.

- 24-hour auto start/stop timer for CCAD-1U ~ CCAD-6U.