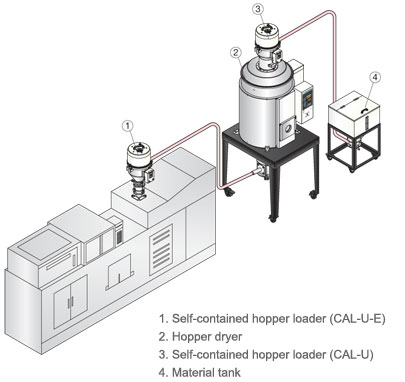

CAL-U Self-Contained Stainless Steel Hopper Loader

Introduction

The CAL-U Series self-contained hopper loaders are used to transfer pellets and regrind from a single source (usually a gaylord) to a single destination (usually a blender, drying hopper, or machine throat) in facilities that do no have centralized conveying systems.

The cost-efficient, stainless steel hopper ensures no material contamination and the soundproof motor cover reduces motor noise. The detachable control panel allows the operator the convenience of remote operation.

Features

- Sound-proof, corrosion free stainless steel interior with no internal protrusions.

- High speed carbon brush motor and fault indicator for a faster rotating speed and commutation.

- User-friendly microprocessor control with fully programmable, easy-to-read interface with functions for filter cleaning time and frequency, load and delay time, and maintenance scheduling.

- Extremely reliable, highly sensitive reed switch on CAL-U or photosensor switch on CAL-U-E for material level detection.

- Quick release, hinged hopper lid ensures quick cleanup time and easy maintenance.

- CAL-6U and above models can select an air accumulator to enhance purging and reduce manual clean time.

- Detachable hand-held control panel for remote operation.

- Run time indicator, reverse stopper flap, automatic cleaning.

- A pendant can be extended up to 50-ft. by using a standard CAT5 cable.

- Cloth mesh filter and auto-spraying dust cleaner.

Options

- Reinforced auto cleaning air accumulator (model CAL-6U and above).

- Regrind mix ratio works with Comet’s CPV-U proportioning valve to enhance mixing.