BMB Blow Molding Booster

Introduction

Comet’s BMB Blow Molding Booster is an internal air cooler system for blow molded parts. It is a simple, safe air chiller designed to reduce material stress and distortion by cooling the internal air of the product during the blow molding process. Cooling time, the longest part of the total cycle time, slows production by reducing cycle times and shrinks profits.

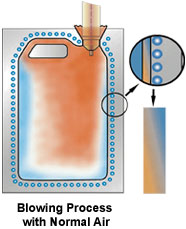

Typically, cooling blow molded products occurs from outside to the inside. Consequently, heat must travel through the entire thickness of the product to cool the inside. Thus, cooling products with thick plastic walls, such as a drum container, can take a significant amount of time and distort the product from its intended shape. In fact, products run with poor cooling come out of the mold too hot and, as the product cools to room temperature, it shrinks and becomes misshapen. If cooling is not improved, the only choice left is to slow the machine down to reduce the rate heat is absorbed by the molds.

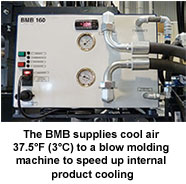

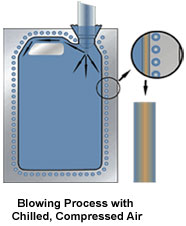

The BMB replaces the regular blown air with chilled, compressed air (37°-41°F/ 1°-5°C) in the internal surfaces of the product during the cooling process to improve cooling efficiency, cut cooling time, and reduce both molding stress and crystallization rates.

Features

- Simple, easy to install and operate, increases production from 15% to 35%.

- Suitable for virtually all extrusion blow molding machines.

- Compact, normally installed on top of the blow molding machine to save factory floor space.

- Quick return on investment (15 – 30 days).

- Maintenance free, no spare parts inventory required.

- Removes heat from the inner surface of the product reducing material stress while cutting cooling and cycle time.

- Capable of handling any quality of compressed air.

- Low energy consumption, CFC-free, ozone friendly.

- Less product distortion due to lower crystallization rates which may enable you to save up to 10% in raw materials.

- Maintains a compressed air supply temperature no higher than 41ºF (5ºC) for the blow molding process.

- Simple blow pin and blow needle designs.

- Many different valve configurations available to handle any blow molding application.

Options

- Customizable blow pin and blow needles designs available.

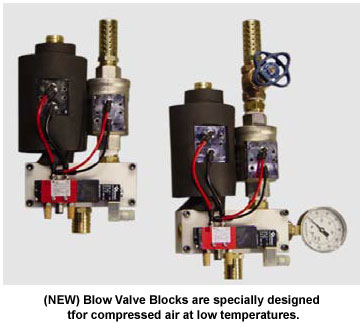

- Blow valve blocks to optimize air exchange.

- Air compressor, air/oil separator, air dryer.

- Control valve for controlling bladder valve blocks.