CAL-UG124 Multi-Loader Conveying System

Introduction

The CAL-UG124 four-station central loading system is designed to convey plastic resins and powders for up to four separate stations. These models are equipped with a high-pressure blower and four CHR-U-S central vacuum receivers to lower production costs. They can be used with four Comet CDD Honeycomb Matrix drying systems or one CGB gravimetric blender to process plastic materials.

This multi-station approach makes the CAL-UG124 an extremely cost-effective way to convey plastic materials to different molding machines or hoppers.

Features

- One main vacuum loader for four hopper receivers, suitable for long distance conveying.

- Conveying plastic materials to different molding machines or hoppers.

- Back-up on E-Prom in case of power failure.

- Air blow-down allows dust removal using a cyclone dust separator.

- Separate stainless steel CHR-U vacuum receivers ensure no material contamination.

- Stainless mesh vacuum filter with removable dust collection bin to remove dust and fines.

- Vacuum relief valve for quick material discharge, maximizing load, and energy consumption.

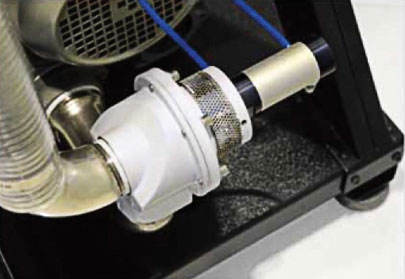

- Vacuum pump includes safety filter, relief valve, and motor control that is all mounted on an industrial frame

with leveling feet. - Motor Overload Indicator and visual alarm.

Options

- CCH-6U/12U/24U heat insulated storage hoppers can be installed on a reed switch storage hopper or directly on an injection molding machine.

- An air accumulator auto purging device.

- Audible alarm buzzer.