DMS Condensation-Free Mold Dehumidifier

Introduction

Comet’s DMS “Dry Mold System” provides a new, energy efficient approach to condensation-free mold dehumidification for injection molding, thermoforming, and blow molding applications. The DMS series is designed to be used for single production machines, or up to three units.

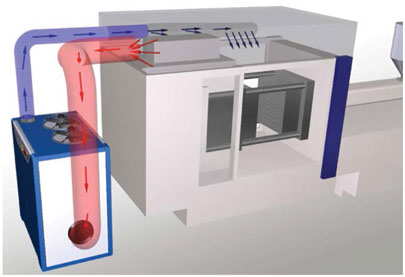

What differentiates the DMS from traditional cooling methods is that the DMS is not constantly dehumidifying the hot, humid ambient air. Instead, process air runs through the DMS in a closed-loop circuit. The DMS starts when moisture in the air is detected. This warm, moist air from the mold area flows into the DMS where it is dehumidified with the aid of a state-of-the-art refrigerant compressor without using any chilled water. The processed air is then returned to the mold area creating a dry environment around the mold and closing the loop. By eliminating the need for a chiller, a shorter cycle time and higher production output is achieved, and profits increase.

Standard dehumidification systems on the market are supplied with a water pre-cooler. The DMS units do not need chilled water for pre-cooling, which automatically reduces overall investment costs. By cutting out the pre-cooler, immense costs and energy savings can be achieved. The DMS control adapts to the required cooling capacity of the ambient conditions, with the help of intelligent sensor technology. The DMS is a tailor-made system, allowing you to choose dry process air volumes from 500 to 3,500 Nm³/hr.

Features

- Dehumidification at low temperatures without the need for chilled water – NO PRECOOLER (chiller) is required.

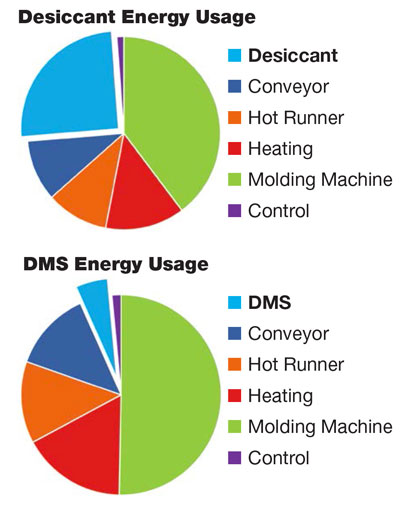

- State-of-the-art refrigeration technology guarantees perfect, consistent conditions at up to 85% energy savings.

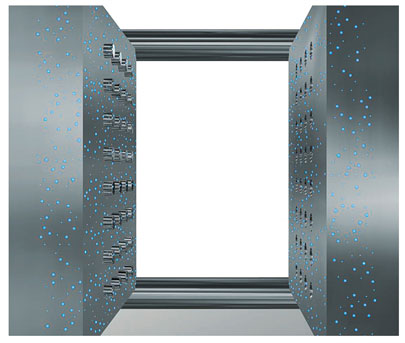

- Uniform product quality and higher production output with condensation-free production conditions.

- Higher machine efficiency through shorter cooling times.

- Suitable for single production machines (or up to three).

- Process air running in a closed-loop circuit for pretreatment and air dehumidification with a dewpoint of 39.2°F (4°C).

- Air-cooled version: zero cooling water. Water-cooled version: works with temperatures up to 90°F (32°C).

- Air volumes from 500 m3/hr up to 3,000… guaranteed to keep your molds dry!

- Compact, can easily integrate into a manufacturing cell due to the marginal foot print it leaves, physically as well as ecologically.

Why Worry About Mold Condensation?

Condensation on a mold leads to possible water marks on the final product causing rejects or low product quality. Even moisture levels of 0.07% can cause cosmetic problems know as splay or silver streaking, an indicator that the material being molded contains too much moisture.

Mold Drying with the DMS = Double Cost Savings!

The DMS’s only connection is to an electrical source, so installing insulated water pipes to and from the chilled water source are no longer required. And, because the DMS has intelligent sensor technology, it adapts to the required cooling capacity of the ambient conditions. There is no additional investment for a chilled water supply. The benefit is double cost savings, once with the initial investment and a second time during operation.