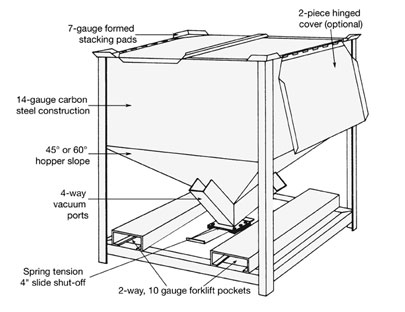

Flo-Thru Hoppers

Introduction

Comet’s Flo-Thru Hoppers are ideal for storing and transporting both dry bulk material and finished product. Gaylords are dumped into the unit via our PowerMaxx, or material can be vacuumed into the units from storage bins. Hopper capacities range from 10 cubic feet to 150 cubic feet. Comet will design and manufacture Flo-Thru Hoppers to meet custom specifications for capacity, angle, material, and discharge.

Features

- Hoppers and frames constructed of heavy-duty carbon steel (304 stainless steel also available).

- Interior and exterior painted warm gray.

- 4″ locking slide gate with spring tension.

- 2-way, forklift pockets for easy transportation.

- 7-gauge stacking pads for fast, safe stacking (up to four bins high).

- 45° or 60° hopper slope to accommodate various material flow characteristics.

- 4-way vacuum ports with dust covers for material discharge through a vacuum wand.

- Mobile, easy to move using a forklift or by simply rolling on optional locking casters.

Options

- Available in various materials, custom shapes, special exterior or interior paint, and epoxy finishes.

- Two 4″ swivel casters and two 4″ locking caster set.

- 2-piece hinged cover, opens from the center to the outside (1-piece solid or with 8″ hole also available).

- 4-way forklift lift entry for pallet jack.

- 4″ sight-glass window for visual inspection.

- 52″ discharge stand opened at one end for accessibility.

- 8″ or 10″ spring tension slide gates without vacuum entries.

- Agitation devices.

- Impact resistant 3″ x 5″ card holder.