Extrusion – ColorSave 1000F

Introduction

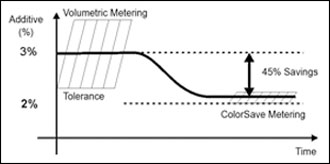

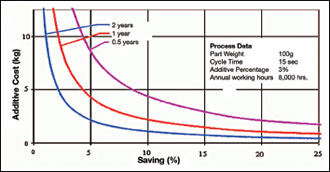

ColorSave 1000F gravimetric feeder for color concentrate and additives is designed to be installed on injection molding machines and extrusion to obtain the highest possible accuracy and mixture consistency. When compared to other volumetric feeders on the market today, the ColorSave 1000F will save up to 50% in color concentrate/additives, save up to 35% when compared to remote batch blenders, and up to 15% compared to on-the-machine throat batch blenders. The diagrams below show the comparative savings calculated on the basis of the actual performance of volumetric feeders.

Features

- Precise, accurate consistency prevents material over-metering

- Loss-in-weight control function for optimum adjustment of the operating point

- Improves final product quality

- Reduces number of rejects

- Simple operation with automatic calibration (zero setup time) ensuring maximum efficiency

- Consistent delivery of shot-weight

- Real-time data collection and management of color concentrate consumption using proprietary control software

- Innovative design and algorithms ensure excellent resistance to mechanical shocks and vibrations

- Integrated automatic Venturi vacuum loader

- Easy replacement of feed screw

- Easy maintenance and cleaning when switching colors

- Compact mechanical design and low hopper profile, suited to any injection molding machine or extrusion

Feed Throat Transitions

Neckpiece (Front)

Neckpiece (Back)

Neckpiece